The demand for high-quality, reliable electronics is higher than ever. However, achieving consistency and dependability in your printed circuit board (PCB) assembly process can be challenging. Unexpected shipping delays, quality issues, and communication hurdles can throw your timeline off track and disrupt your production goals.

When you prioritize PCB assembly in the USA, you gain more than a supplier—you gain a strategic partner that prioritizes quality, offers quicker lead times, and provides seamless communication. Whether you’re developing medical devices, defense technology, or cutting-edge industrial products, working with a U.S.-based PCB manufacturer ensures smoother operations and a superior end product.

Understanding PCB Assembly

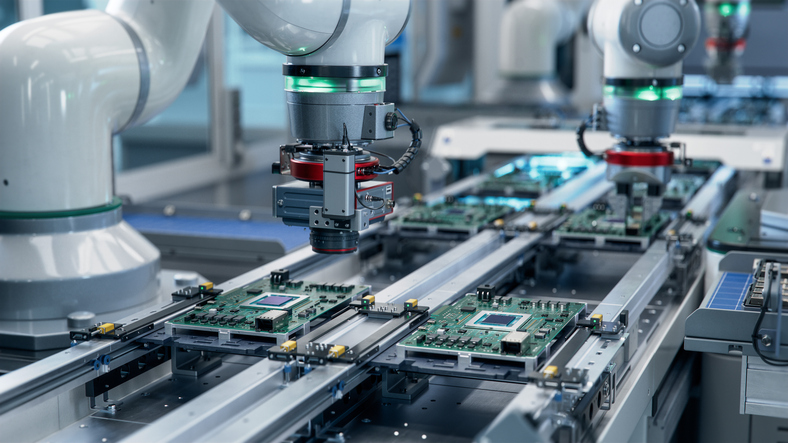

Printed Circuit Board (PCB) assembly involves soldering electronic components onto a PCB to create functional circuits. It’s a critical step in manufacturing electronic devices, requiring precision, quality control, and expertise to ensure reliability. Whether you’re producing medical devices, aerospace technology, or consumer electronics, the quality of your PCB assembly can make or break your product. Choosing PCB assembly in the USA provides distinct advantages that can streamline your production process, enhance product quality, and reduce risks. Here are 10 reasons why partnering with a U.S.-based PCB assembly provider is a strategic choice for your business.

1. Unmatched Quality Standards in PCB Assembly USA

PCB assembly providers in the USA follow stringent industry standards, such as IPC-A-610, for assembly quality. Industry standards ensure your boards are assembled precisely, minimizing defects and maximizing performance. For reliable results, many American companies also invest in advanced inspection methods, such as automated optical inspection (AOI) for part placement, automated inspections, and X-ray analysis.

2. Shorter Lead Times with Domestic PCB Assembly

When you choose PCB assembly in the USA, you benefit from faster turnaround times. Local suppliers eliminate the delays associated with overseas shipping and customs, helping you meet tight deadlines and adapt quickly to changes in demand or design.

3. Enhanced Communication and Collaboration

One of the key advantages of working with a U.S.-based PCB assembly provider is seamless communication. Being in the same time zone and speaking the same language allows for faster feedback, clearer instructions, and smoother project management. This ensures that your project runs efficiently from start to finish.

4. Environmental and Regulatory Compliance

PCB assembly providers in the USA adhere to strict environmental and safety regulations, including compliance with RoHS (Restriction of Hazardous Substances) and avoiding the use of conflict minerals. Local production also reduces the carbon footprint associated with long-distance shipping, aligning with sustainability goals and corporate responsibility initiatives.

5. Supporting the U.S. Economy

Partnering with an American company for PCB assembly supports local jobs and stimulates economic growth. By choosing PCB assembly in the USA, you help foster innovation and contribute to workforce development within the domestic electronics manufacturing industry.

6. Supply Chain Stability and Risk Reduction

Global supply chain disruptions have highlighted the importance of reliable sourcing. Choosing PCB assembly in the USA reduces the risks associated with international trade, such as shipping delays, tariffs, and geopolitical uncertainties. This stability ensures a consistent production schedule and minimizes costly disruptions.

7. Intellectual Property Protection with PCB Assembly USA

Protecting your intellectual property (IP) is critical when manufacturing electronic products. U.S. PCB assembly providers operate under robust IP laws, safeguarding your designs and proprietary technologies. This protection gives you peace of mind and ensures your innovations remain secure.

8. Customizable Solutions for Complex Projects

PCB assembly providers in the USA excel in offering tailored solutions to meet unique project needs. American suppliers provide the flexibility and expertise you need, whether you require high-mix, low-volume production, or advanced assembly techniques like surface-mount or through-hole technology.

9. Protection from Counterfeit Components

Counterfeit electronic components cost the industry hundreds of billions of dollars, with obsolete components being the most likely counterfeited and active components with long lead times being close behind. Working with an American PCBA provider following counterfeit mitigation standards will ensure you get original components, protecting your products from premature or intermittent failure.

10. Government Incentives Supporting PCB Assembly in the USA

Government programs like the CHIPS and Science Act provide incentives to bolster domestic electronics manufacturing. By choosing a U.S.-based PCB assembly partner, you benefit from these initiatives, which strengthen supply chains, enhance technology, and ensure long-term stability in the industry.

Why PCB Assembly in the USA is a Smart Investment

When you choose PCB assembly in the USA, you’re investing in more than just production—you’re prioritizing quality, efficiency, and security. From shorter lead times and robust IP protection to enhanced communication and advanced customization options, American PCB assembly providers offer the reliability and expertise your business needs to succeed.

Ready to get started? Contact us today to learn how our PCB assembly capabilities can help you streamline production, reduce risks, and deliver better products faster.