Military electronics must withstand soaring temperatures, strong winds, and harsh environments. Despite this, military electronic parts must contend with these rugged conditions and function flawlessly. Electronics play a critical role in modern military operations, from communications to weapons systems and more. Let’s explore how military-grade electronic components are specially engineered to perform in extreme environments, and how Siemens Manufacturing supports this with our expert services.

A Closer Look at Military Environments

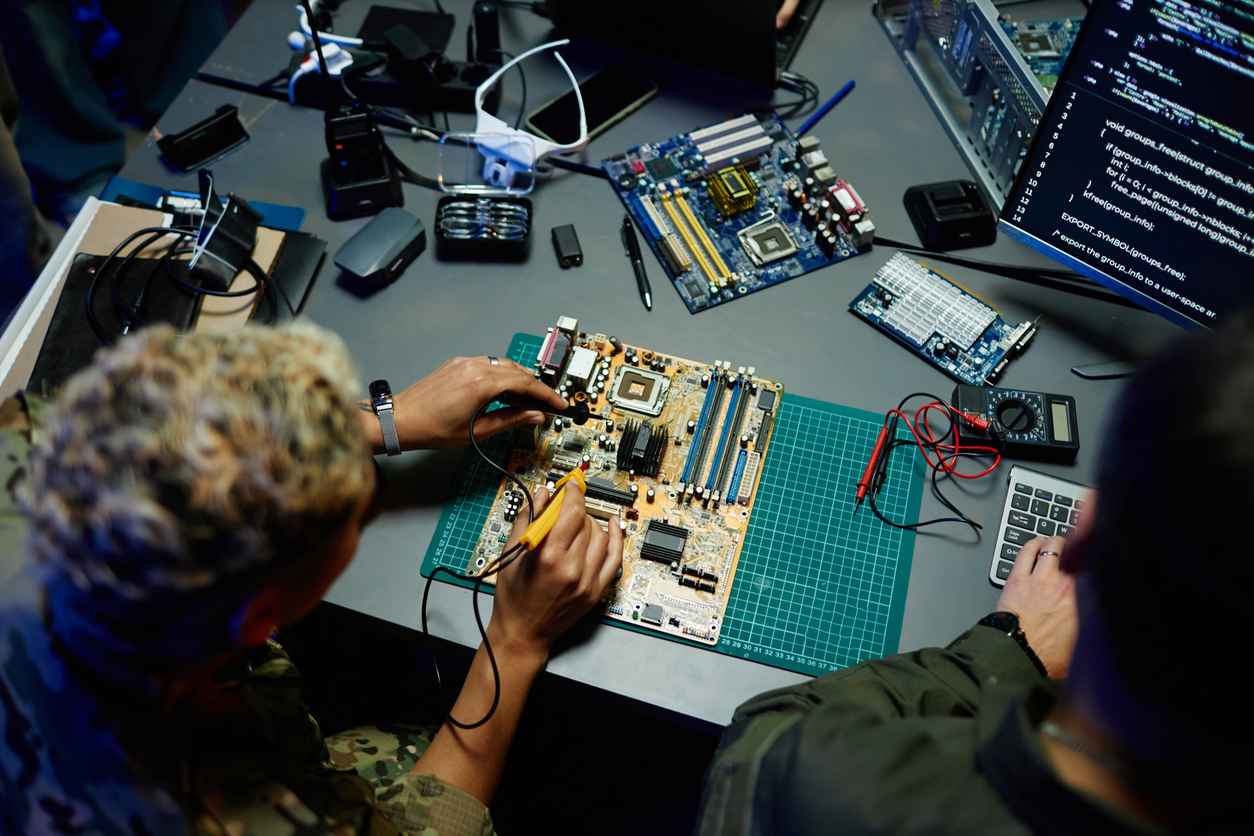

Military electronic components must grapple with various environmental challenges, which includes extreme temperatures, humidity, vibration, and corrosion. In addition, these components must withstand electromagnetic interference, and altitude challenges, as well as sand, dust, and chemical exposure.

These challenges matter, because these military products are used in scenarios where failure is not an option, such as battlefield communications, avionics, and naval radar systems. Key design considerations for military electronic parts include:

- Material selection: It’s crucial to use corrosion-resistant materials and utilize conformal coatings for added PCB protection.

- Thermal management: Ensure your components are designed for passive and active cooling so that your military electronic parts can withstand extreme temperatures.

- Mechanical durability: While designing your project, consider if you’ll require ruggedized, shock-absorbing, and vibration-resistant parts.

There are certain design and production standards in the military sector that require compliance. Adherence here is critical, as it can affect government procurement, safety, and performance, so testing and validation services are important.

How Siemens Manufacturing Supports Military Electronics

At Siemens, we have extensive experience serving the military market. We’ve crafted circuit board assemblies, rugged box build assemblies, and more. With unique testing requirements that must be met, this market needs an experienced and knowledgeable manufacturer.

We offer scalable production and a deep commitment to quality because we understand the importance of military electronic parts performing as expected. Our DFM support entails early collaboration with OEMs in order to improve performance and reduce costs.

With our trusted supplier network, Siemens Manufacturing offers material sourcing and component traceability, as well as counterfeit mitigation strategies. Our PCB testing services include in-circuit testing, functional testing, Automated Optical Inspection, lot traceability, Thermal Chamber testing, ESS (Shake Table) Testing and more.

At Siemens, we offer tailored solutions for the military sector, as well as responsive project management and support. Military environments demand the highest level of engineering precision and ruggedness, and Siemens Manufacturing is uniquely prepared to deliver excellent results that perform under the harshest conditions. Reach out to our team today to get started.