When developing a new electronic product, the quality and performance of its printed circuit board (PCB) determine much of its success. Prototype PCB Assembly is a critical step in bridging the gap between conceptual design and production. While it may seem like a preliminary step, its impact on design validation, performance, and long-term reliability cannot be overstated.

Identifying and Resolving Design Weaknesses

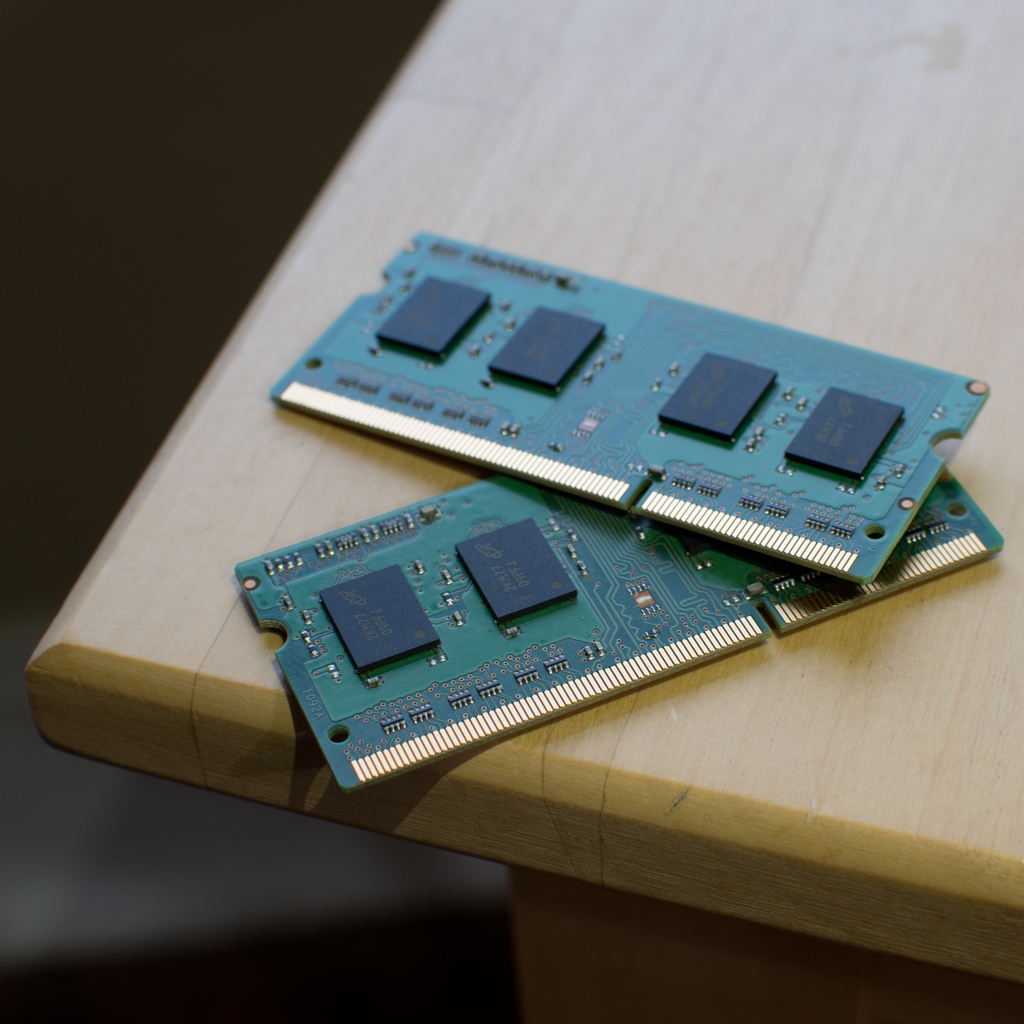

Design software and simulation tools provide accurate models, but a physical prototype can provide much more insight. Assembling and testing an actual board exposes unknowns that virtual testing cannot, such as thermal behavior, trace interference, or subtle component misalignments. Engineers can physically handle, measure, and analyze how the board behaves under load, allowing them to correct layout flaws before they escalate into performance issues.

A prototype functions as a reality check. It verifies whether theoretical tolerances hold up under actual manufacturing conditions. This step eliminates uncertainty early in the process, helping both engineers and customers feel confident that the product design is sound before investing in full production.

Confirming Component Performance and Placement

The layout of a PCB is concerned with how components interact, as well as their placement. During prototype assembly, engineers verify that each part functions as intended within the system, ensuring that electrical signals flow correctly and that temperature and power demands remain within specified limits. Component orientation, spacing, and solder joint quality are closely examined, as even slight deviations can impact long-term performance or manufacturability.

Testing component behavior in a real-world configuration provides valuable insight into the board’s durability and service life. Adjustments to component placement or trace routing can improve efficiency, reduce heat buildup, and optimize the product for its final operating environment. This stage ensures that when the design reaches production, every component contributes to consistent, repeatable performance.

Refining Functionality and Verifying Reliability

A functioning prototype allows engineers to perform detailed operational testing. Electrical performance, thermal stability, and signal integrity can be measured and compared against expected values. This testing confirms that the design meets performance requirements and does so reliably over time. Functional verification is particularly important for applications that demand precision, such as medical instruments, industrial controls, or aerospace systems.

The prototype also allows for incremental improvement. Engineers can experiment with material selections, component alternatives, or assembly techniques to refine the product for optimal results. Skipping or minimizing the prototype stage increases the chance of encountering problems once production begins, when corrections are far more disruptive.

Prototype PCB assembly mitigates this risk by validating every assumption in a controlled, low-volume setting. It confirms that both the design and the assembly process can be repeated accurately at scale. Each successful prototype iteration strengthens the final design, reduces uncertainty, and builds confidence in the overall design. For customers, that means fewer surprises during production, stronger product reliability, and a shorter path to market.

Smoothing the Transition from Design to Production

Moving from engineering design to full-scale manufacturing can be one of the most challenging steps in product development. A prototype PCB serves as a blueprint for the production team, clarifying assembly steps, soldering profiles, and quality checkpoints. It exposes manufacturability concerns that could affect yield or throughput, such as component spacing, stencil design, or reflow behavior.

By identifying these factors early, companies streamline the production process and avoid late-stage rework or delays. A complete and thoroughly tested prototype package, along with validated documentation, ensures that both the customer and the manufacturer share a clear understanding of the requirements. This preparation enables faster ramp-up times and smoother handoffs when the product transitions to higher volume production.

Supporting Compliance and Quality Assurance

Many industries operate under strict performance and safety standards. Prototype PCB assembly offers the first opportunity to confirm that a product meets these requirements before it advances to the certification phase. Testing can include evaluations of electrical safety, signal performance, and environmental stress to help ensure compliance with standards such as IPC, UL, or ISO.

Documenting the testing and refinement process also strengthens traceability, which is often required in regulated sectors. Customers gain assurance that every design decision has been validated and recorded, supporting a transparent quality management approach. This early alignment with compliance expectations reduces risk and supports a smoother certification process later.

The True Value of Prototype PCB Assembly

Prototype PCB assembly is a process that protects the integrity of your design and the reputation of your brand. It enables better collaboration between engineers, manufacturers, and stakeholders, aligning everyone on the performance goals of the final product.

At Siemens Manufacturing, prototype PCB assembly is treated as a critical step in ensuring reliability and repeatability. Our engineering and production teams work closely with customers to validate every detail from layout verification to component sourcing so that when a design moves to production, it performs as intended.

For customers seeking dependable manufacturing partners, Siemens Manufacturing combines technical expertise with a proven quality process to deliver prototypes that pave the way for long-term success. The value lies in building products that not only function but also endure; proof that every successful launch begins with a well-executed prototype.

Ready to move your design from concept to production with precision and reliability? Contact Siemens Manufacturing to discuss your prototype PCB assembly needs and learn how our team can help you bring your next project to life.