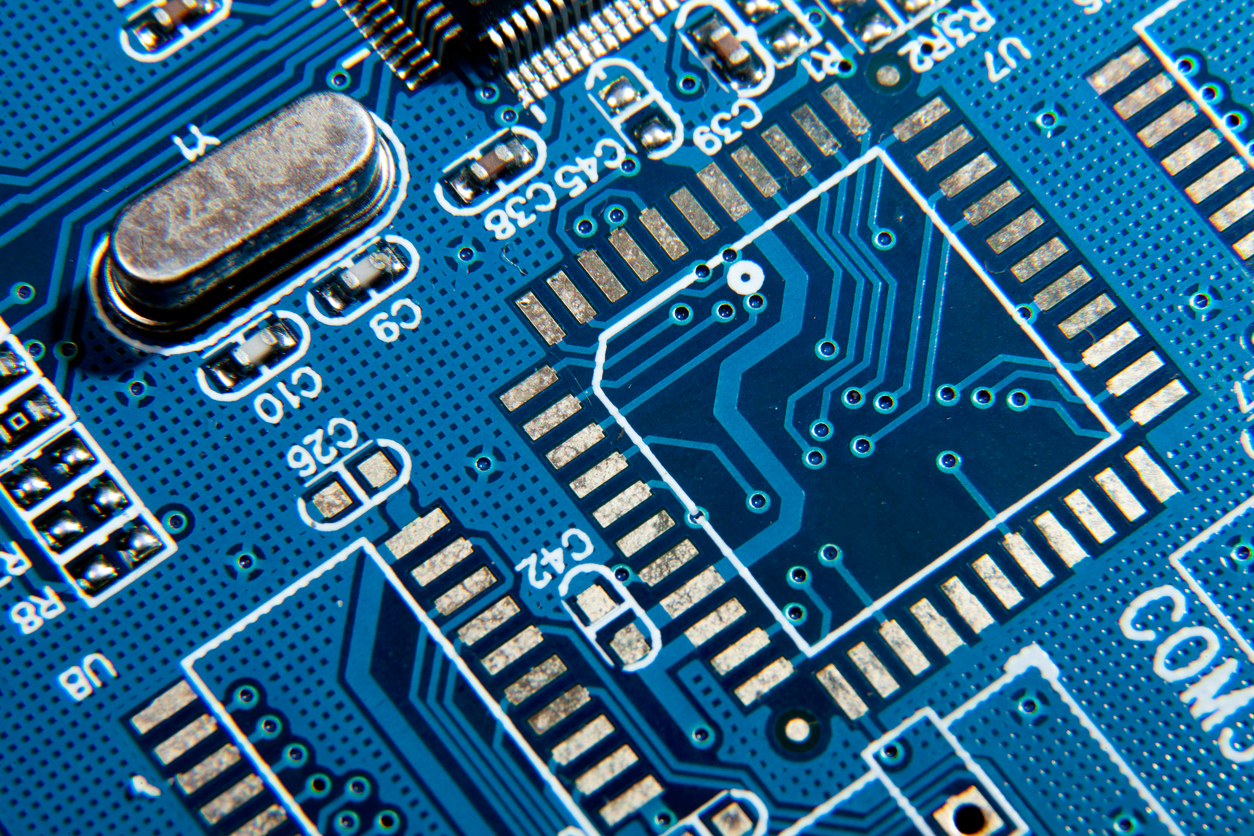

PCBA manufacturing quality directly affects product reliability, safety, and longevity, so it’s essential to partner with the right manufacturer that will prioritize your project. When it comes to manufacturing processes, through hole assembly remains crucial, despite the rise of surface mount technology. Let’s take a closer look at how to evaluate a PCBA manufacturer for through hole assembly and how Siemens Manufacturing acts as a superior choice.

Understanding Through Hole Assembly Services

Through hole assembly involves assembling electronic components by inserting their leads through holes that are drilled in a PCB and then soldering them on the opposite side. In contrast, with surface mount technology, components are placed directly onto pads on the surface of the board and then soldered. Some industries that are still dependent on through hole assembly include automotive, aerospace, industrial, and medical equipment. Types of THA techniques include manual soldering, wave soldering, and selective soldering.

With this process, you can expect stronger mechanical bonds and higher current-carrying capacity. In addition, THA offers greater durability, especially in harsh environments. While surface mount technology prioritizes speed and complexity, through hole assembly prioritizes strength and reliability. Many modern PCBA manufacturers use both processes in order to craft efficient, quality products.

Choosing the Right PCBA Manufacturer

Manufacturers have an immense impact on product reliability and performance, as well as cost and lead time considerations. Poor through hole assembly oversight increases rework, delays, and field failures, which is why DFM is so critical. Choosing the wrong manufacturer can lead to solder cracks, improper thermal profiles, misaligned components, and inadequate inspection, as well as supply chain issues and counterfeit parts risks.

There are several key criteria to evaluate when selecting a PCBA manufacturer for through hole assembly services. First, evaluate their technical capabilities and expertise within different industries to ensure they can handle your specific application. Consider their quality certifications and dedication to compliance to make sure your product will adhere to industry standards.

Additionally, take a look at your PCBA manufacturer’s inspection and testing capabilities, as well as their component sourcing and supply chain reliability. Evaluate their DFM support and early engineering feedback, as well as their transparent communication and customer service. Make sure your PCBA manufacturer will fit your project specifications and work to produce the highest possible quality.

How Siemens Manufacturing Stands Apart in Through Hole Assembly

At Siemens, we offer a variety of expert PCBA manufacturing services, including through assembly. Our through hole capabilities include eight wave solder lines between all of our facilities and four selective solder lines. We utilize robotic soldering, two axial insertion machines, and two DIP insertion machines, allowing us to maximize both efficiency and quality. Our team is able to work with tens of thousands of boards per day.

Quality and reliability are at the forefront of our business. We offer in-circuit testing, functional testing, automated optical inspection, and more, and we also hold an ISO 9001:2015 certification. With our comprehensive DFM support and supply chain strength, our customer-centric approach will maximize the value of each project.

Choosing the right through hole assembly-capable PCBA manufacturer is essential, and Siemens Manufacturing uniquely delivers superior quality, reliability, and service. Are you ready to maximize the durability and strength of your next project? Request a quote today to get started.