In the custom electronics industry, it’s important to utilize processes that enhance efficiency and quality without sacrificing overall budget. That’s why ball grid array (BGA) assembly is such a vital service. Used in a variety of industries, including consumer electronics, medical devices, automotive and much more, BGA assembly offers many benefits. Here, we will take a comprehensive look at BGA assembly, as well as its advantages and applications, and then investigate why Siemens Manufacturing is the perfect partner for your BGA assembly services.

Looking for custom electronics manufacturing? Turn to the expert team at Siemens Manufacturing to get started on your next project.

What is BGA Assembly?

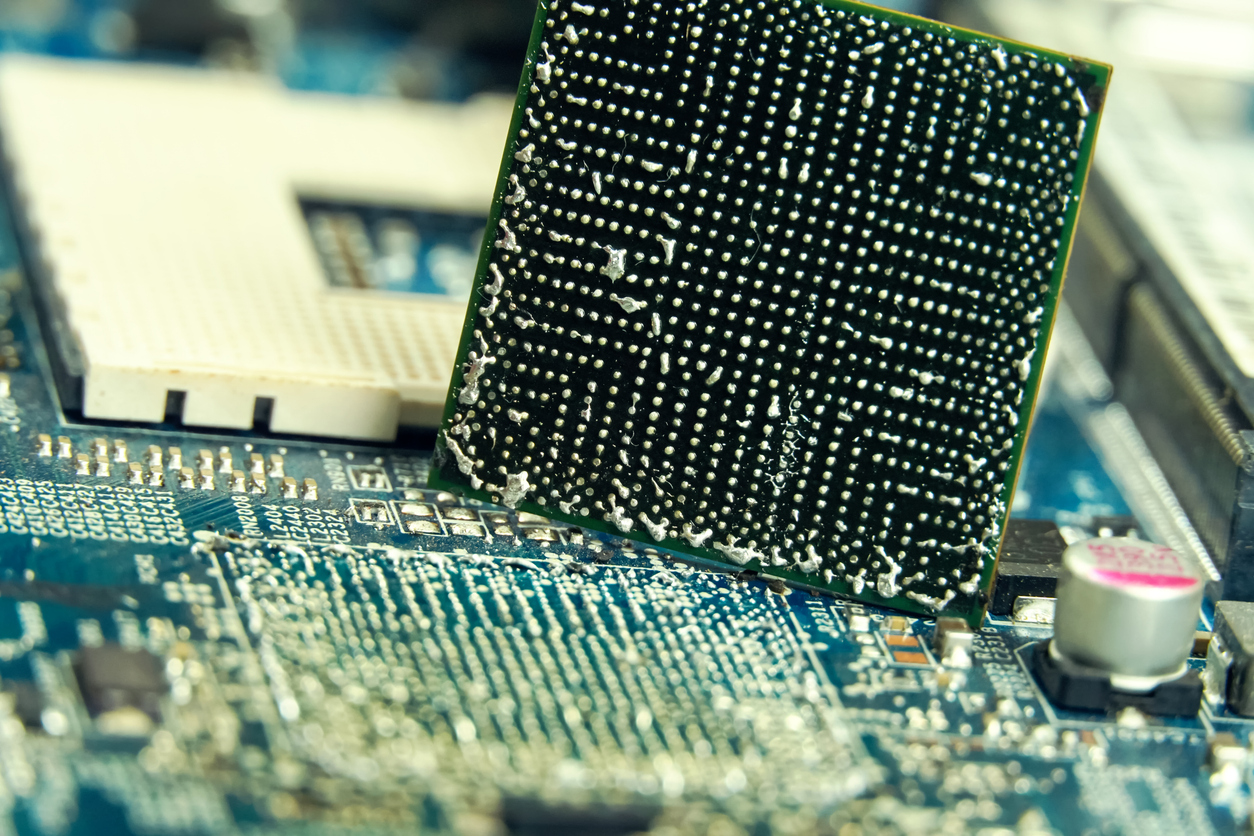

First, it’s important to understand what BGA assembly is. Ball grid array (BGA) components contain an array of solder balls on the bottom of the part to the printed circuit board. Assembly consists of attaching a BGA component to a printed circuit board using the solder reflow process. This process can offer many benefits. Let’s dive in.

The Advantages of BGA Assembly

BGA assembly can result in enhanced performance. The short distance between solder balls reduces inductance, which is the property of an electrical conductor to oppose any change of electric current flowing through it. With this reduction of inductance, you can expect improved performance and speed.

Another advantage is that BGA assemblies offer a more compact design, reducing the overall thickness of the board. This process is also more suitable for automation, leading to greater overall efficiency. BGAs offer higher pin density and more advanced heat conduction and thermal management. Because BGA leads are made from solid solder balls, you can also expect a boost in overall quality, which reduces maintenance costs, making it a more cost-effective option that doesn’t sacrifice performance.

Trust Siemens Manufacturing for Superior BGA Services

Clearly, BGA assembly services can offer many enticing advantages, and Siemens Manufacturing is the perfect partner for this beneficial process. Since 1963, we’ve adopted a comprehensive client-first approach that ensures we’re providing the highest possible quality electronics manufacturing services to our customers.

Our BGA services are thorough and robust. At Siemens Manufacturing, our surface mount lines place thousands of BGAs per week. Our BGA placement and reflow processes are highly controlled, allowing us to reduce potential defects and optimize product value for our customers.

In addition, you can expect a wide range of other capabilities from Siemens Manufacturing, including surface mount assembly, through hole assembly, box build, product testing, and much more. We are proud to provide multiple markets with our quality EMS solutions, such as the automotive, industrial, and medical sectors.

With our list of expansive locations in the United States and in Mexico, we are well-equipped to offer our valued customers exceptional custom electronics manufacturing solutions. Quality is at the heart of everything we do, and we’re committed to continually improving our processes to better serve our customers. Our quality assurance process includes in-circuit testing, automated optical inspection, ISO 9001:2015 certification, lot traceability, and much more.

At Siemens Manufacturing, we’re eager to provide you with exceptional BGA assembly services and more. If you’re ready to level up your next project, get in touch with our expert team today.