Electronics play an important role in the medical device industry, which has recently boomed due to the demands of an aging population. The number of Americans aged 65 and older is projected to increase 47% to 82 million by 2050, demonstrating the need for quality medical devices. It’s important to ensure reliability and longevity in these critical applications, and PCB conformal coating is an ideal protective solution. Let’s take a closer look.

Why Protection is Crucial for Medical Device Electronics

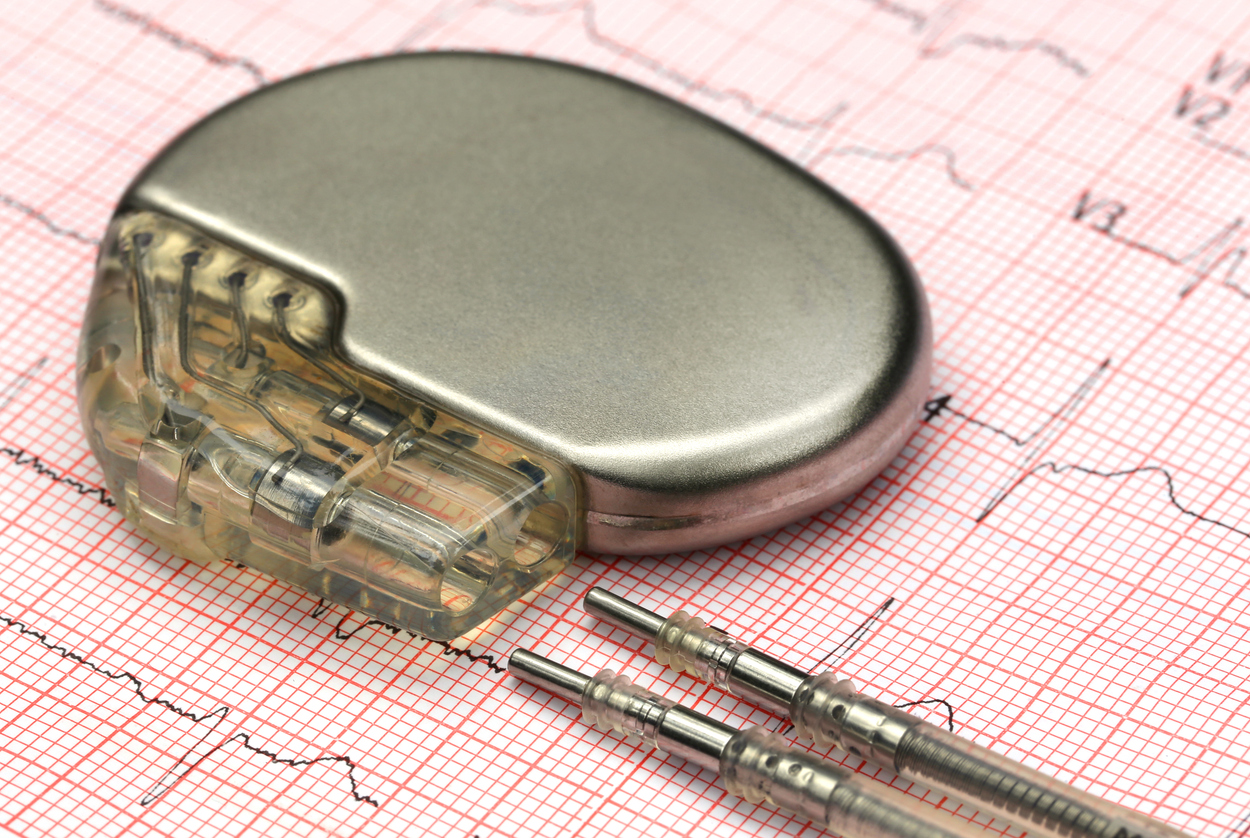

When exposed to moisture, chemicals and bodily fluids, medical device electronics risk corrosion, short circuits, and overall component failure. Some examples of these products include pacemakers, glucose monitors, ECG devices, ventilators, and diagnostic imaging. These electronics are used in life-or-death applications, so precision is mandatory.

For instance, pacemakers are implantable devices that send electrical impulses to the heart to regulate its rhythm, improving overall heart function and saving lives in the process. It’s imperative that such electronic devices are protected from performance failure, which is why PCB conformal coating is an ideal solution.

What is PCB Conformal Coating?

PCB conformal coating involves applying a protective layer to an electronic component. Typical application methods include spraying, dipping, or brushing. Various types of conformal coatings include acrylic, which protects against moisture and dust, and polyurethane, which is easy to apply and provides PCBs with chemical resistance. Silicone is another option which protects against thermal shock. Epoxy provides extreme hardness and parylene offers consistent, uniform coverage.

PCB conformal coating can be beneficial for medical devices. It offers environmental protection against moisture, dust, and other chemical contaminants, as well as improved electrical insulation. PCB conformal coating also provides mechanical protection against abrasion and thermal stress. Because this process prevents corrosion and electrical failure, it also results in improved reliability and longevity for important medical device electronics.

When considering how to utilize this valuable process in medical applications, it’s important to evaluate the conformal coating’s biocompatibility and toxicity. Also consider compatibility with different sterilization methods, and ensure your PCB conformal coating is applied with your required thickness and uniformity.

Partner with Siemens Manufacturing for Exceptional Results

The most important consideration for your PCB conformal coating is selecting the right manufacturer, and that’s where Siemens Manufacturing comes in. All of our facilities use advanced automated conformal coating equipment that applies silicone, urethane, and acrylic variations.

In addition to our conformal coating services, we also have other extensive capabilities that will exceed your expectations, including surface mount assembly, through hole assembly, BGA assembly, automated optical inspection, and much more. We also have vast experience serving the medical market, making us well-equipped to provide you with the quality medical device electronics you need.

Siemens Manufacturing is committed to quality and adherence to regulatory standards, which is particularly important in the medical industry. We offer in-circuit testing, functional testing, lot traceability, and much more. We’re also ISO 9001:2015 certified, and we’re dedicated to getting your project right the first time.

When it comes to your medical electronic components and assemblies, protection is key in extending product life and ensuring reliability. Discover how Siemens Manufacturing can help you improve your medical devices with our PCB conformal coating services.