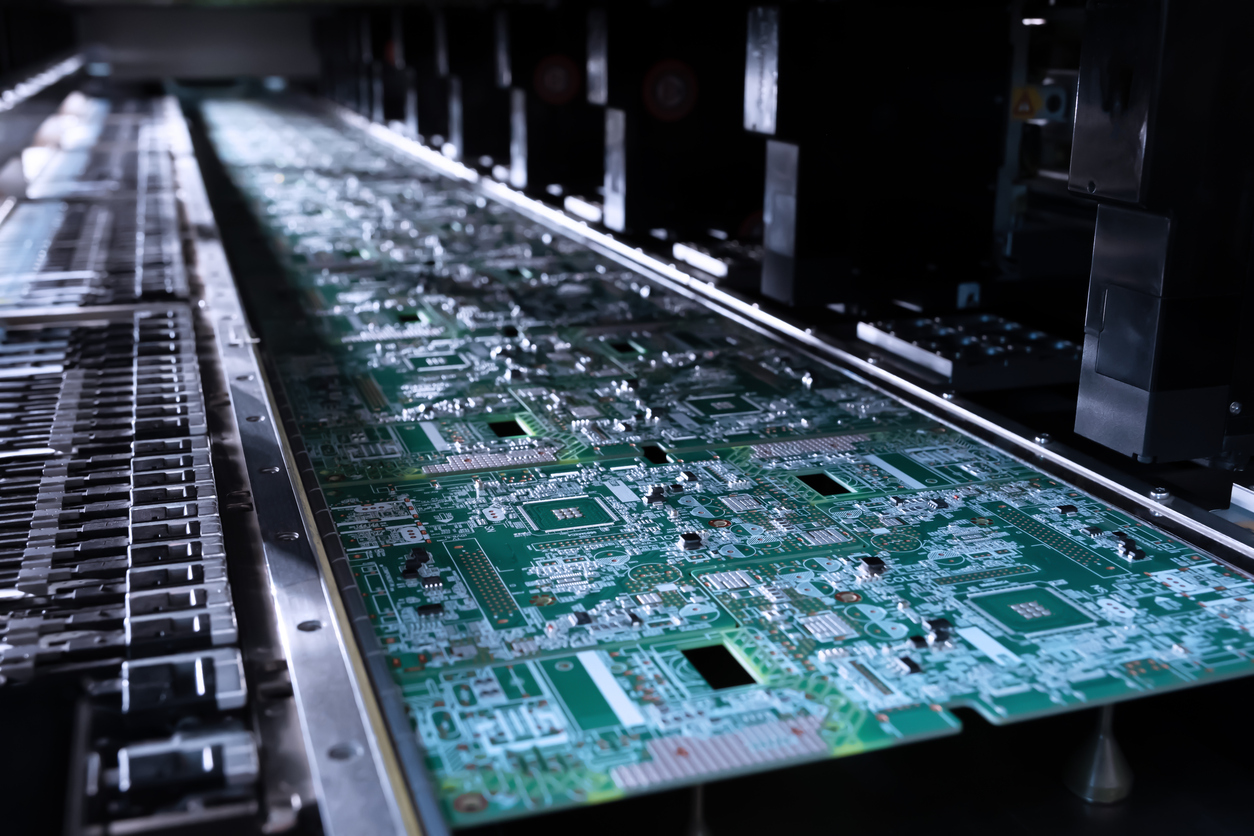

Efficiency is everything to most OEMs, and it’s vital that each manufacturing process reflects this priority. That’s why surface mount contract manufacturing is ideal. This assembly method involves placing components directly onto the surface of a printed circuit board. Utilizing solder paste and reflow soldering, this process results in smaller and denser designs. Let’s take a closer look at the top five benefits of surface mount contract manufacturing and how Siemens Manufacturing can elevate the standard of your next project.

#1: Increased Production Efficiency

Surface mount technology (SMT) allows for faster assembly compared to traditional through-hole methods. Instead of drilling holes for component leads, SMT enables high-speed placement of thousands of components per hour, transforming a long and laborious process into one that is efficient and precise. At Siemens Manufacturing, our high-speed equipment includes eight surface mount lines that allow us to place 1 million surface mount parts a day. Our state-of-the-art SMT lines support our lean manufacturing services and allow us to increase efficiency.

#2: Reduced Manufacturing Costs

Because of this added efficiency, surface mount contract manufacturing reduces both labor costs and material waste. By enabling high-volume production, speeding up manufacturing, and reducing manual labor, SMT optimizes costs. At Siemens Manufacturing, we offer cost-effective solutions and value engineering services. Our flexible capabilities help our customers maximize the value of their products, enhancing speed to market from prototype through final production and optimizing costs.

#3: Improved Product Quality and Reliability

The surface mount contract manufacturing process leads to better solder joint reliability and component placement accuracy, resulting in better overall quality. Automation reduces errors and more compact designs lead to better thermal performance. At Siemens Manufacturing, our comprehensive quality assurance process guarantees that our customers’ needs are met. Our quality assurance process includes in-circuit testing, functional testing, automated optical inspection, lot traceability, and more. In addition, we are also proud to hold several key industry certifications, such as ISO 9001:2015, which holds us to a higher standard of excellence.

#4: Scalability and Flexibility

Because our SMT lines can handle both low- and high-volume production runs, Siemens is able to scale production volume quickly. We respond to customer needs fast, resulting in more comprehensive support and faster turnaround times. We understand the value of efficient results, and ensure that you have the parts you need exactly when you need them.

#5: Access to Engineering Expertise

Our contract manufacturing experience in DFM helps improve product performance and manufacturability. We provide collaborative design support that ensures your products are manufactured, assembled, and tested both efficiently and cost-effectively. With our engineering expertise, you can reduce errors, save costs, and match your precise specifications.

Siemens Manufacturing Rises Above the Rest

At Siemens Manufacturing, we’ve been industry leaders in the custom electronics manufacturing sphere for decades. In 1987, we became the first contract assembler in the St. Louis area to introduce surface mount capabilities, and we understand the importance of speed-to-market and outstanding customer support. With our custom solutions, you can expect to maximize the value of our surface mount contract manufacturing services. Are you ready to partner with a proven, reliable SMT contract manufacturer? Reach out to Siemens Manufacturing today.