Your electronic assemblies deserve the ultimate protection in order to enhance durability and boost performance. It’s important to ensure they undergo valuable safeguarding processes, such as conformal coating.

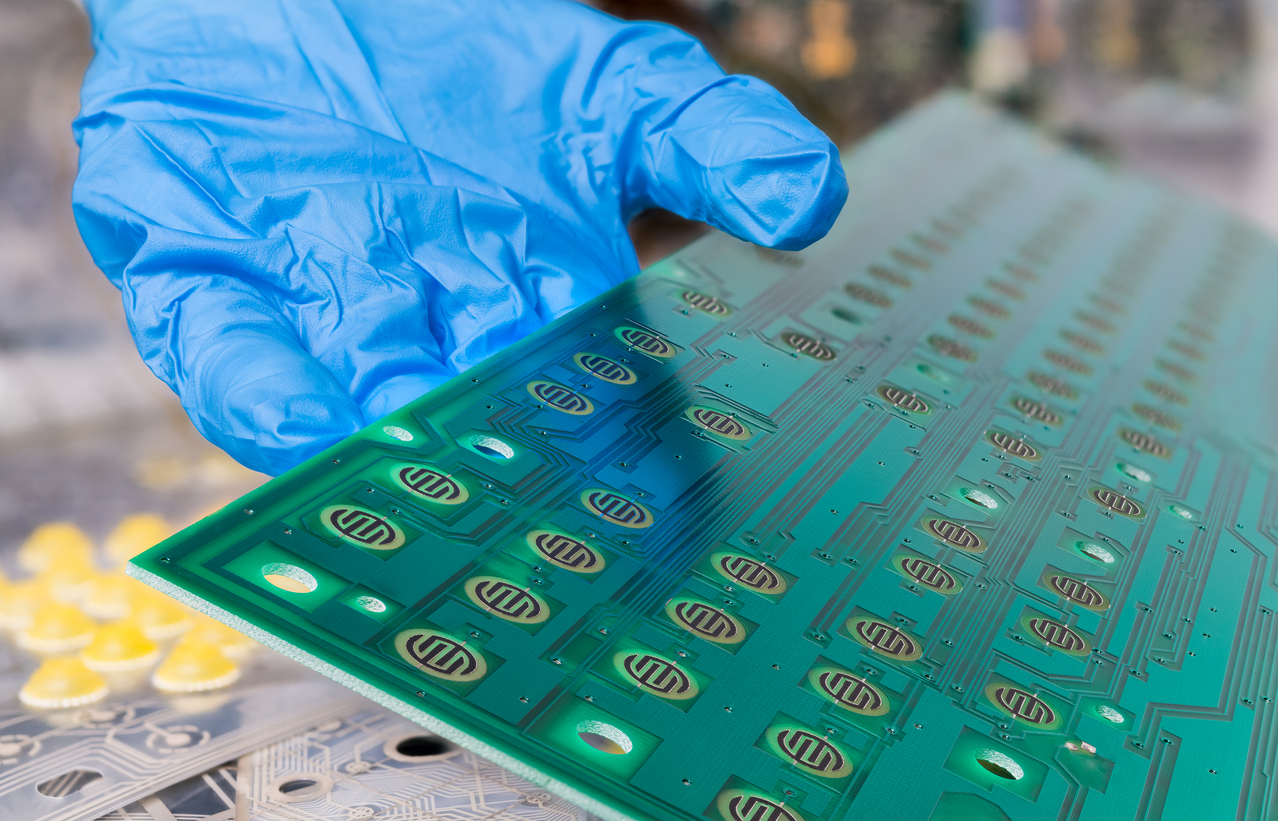

During the conformal coating process, a thin, polymer film is applied to circuit boards as a protective measure. Here, we will outline the benefits of this process so you can understand how it may improve the performance of your electronic assemblies.

Siemens Manufacturing can raise the level of your next electronics manufacturing project. Connect with us here to learn how.

A Closer Look at the Application Process

There are various methods involved in the conformal coating application process. These coatings can be applied through spraying, dipping or brushing.

Traditional conformal coatings have a resin base, such as acrylic, silicone, or urethane resin, and can be diluted with a solvent. While these types of coatings are not fully waterproof, they do provide resistance to outside contaminants which ultimately improves PCB performance.

Another application method involves epoxy conformal coating, which creates very hard and durable coatings. These, however, are difficult to remove. Epoxy coatings have very high chemical resistance and are ideal for potting components.

Parylene film coatings are applied by vapor phase deposition and can be applied very thinly. These types of coatings are very resistant to moisture and extreme temperatures, making them an ideal choice for assemblies that need to withstand tough conditions.

Advantages of Conformal Coating

Electronic assemblies can encounter several issues that can impact or even hinder performance. Moisture can infiltrate assemblies and lead to corrosion and damage. Extreme temperatures can also lead to damage and performance degradation, as can bending or dropping assemblies. Conformal coating can help protect assemblies from these elements. It creates a strong barrier between moisture, chemicals, and corrosive contaminants.

It can also improve functionality and overall quality because conformal coating protects against dust, abrasion, and extreme temperatures. It insulates circuits thermally and electronically, which can prevent performance issues. Conformal coating ultimately extends product life, which can save you money in the long run.

Trust Siemens Manufacturing for Exceptional Conformal Coating Services

At Siemens Manufacturing, we are well-equipped to provide you with comprehensive conformal coating services that will enhance the performance of your electronic assemblies. We have automated coating equipment in all three of our plants, which allows us to provide customers with efficient, quality products while maximizing production time.

Our conformal coating services are comprehensive. We have the capabilities to apply silicone, urethane and acrylic coatings, and we also work with outside vendors to apply parylene coatings. Siemens also has UV cure capabilities, allowing for rapid drying of coatings. With our services, we are able to achieve the most durable results for your electronic assemblies during the conformal coating process.

Experience the Siemens Manufacturing Difference for Yourself

For over 60 years, we have been leaders in the electronics manufacturing world, and we’re prepared to offer our customers with exceptional conformal coating solutions. We also have a wide array of custom electronics manufacturing capabilities, such as surface mount assembly, BGA assembly, box build assembly, and much more.

We also understand the unique needs of different industries, and have experience serving a diverse range of markets, including automotive, industrial, construction, military and more. At Siemens, quality is one of our top priorities. We employ a comprehensive quality assurance progress, which includes in-circuit testing, automated optical inspection, functional testing, and lot traceability. We are ISO 9001:2015 registered, as well as IPC-A-610 Class 2 and a UL recognized electronic assembly program. Our certifications hold us to a higher standard of excellence, allowing us to provide you with the exceptional quality services you deserve.

If you’re ready to level up the quality of your electronic assemblies, consider conformal coating services from Siemens Manufacturing. Get in touch with us today to learn more about how we can help you.