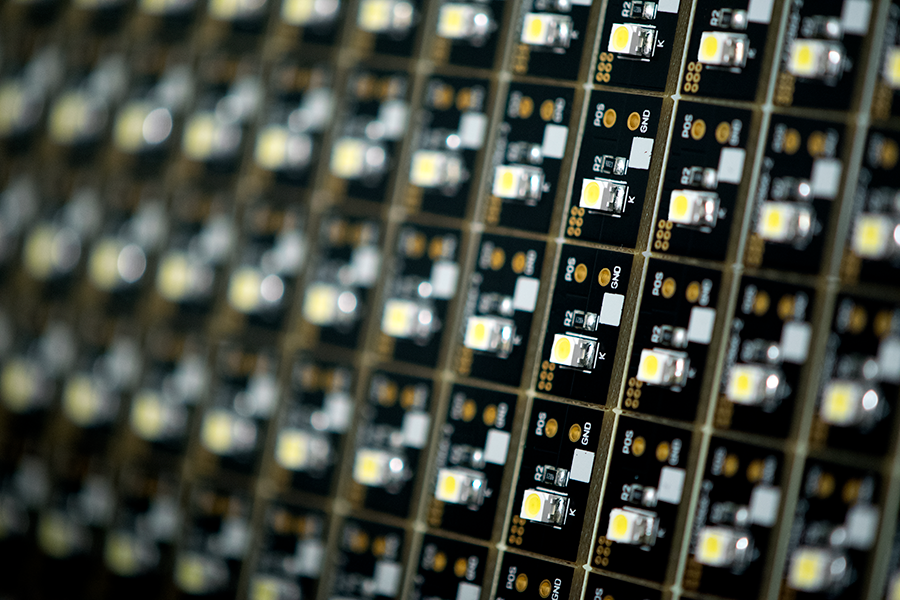

Our PCB Quality Assurance

At Siemens Manufacturing, we have an ongoing commitment to providing high-quality electronics manufacturing solutions to customers in a diverse range of markets. With our innovative capabilities, statistical process controls, customized product testing, and component-level lot traceability, we have the necessary resources to ensure our customers’ needs are met.

Our PCB quality assurance process includes:

- In-circuit testing

- Functional testing

- Automated Optical Inspection

- Lot traceability

- ISO 9001:2015 certification

- IPC-A-610 Class 2 [Class 3 upon request]

- UL recognized electronic assembly program [ZPVI2]

Quality is at the forefront of everything we do at Siemens. Connect with us today to get started on your next project.