In custom electronics manufacturing, quality is essential. There are numerous manufacturing methods available that can boost product quality, but one of the most prevalent is surface mount technology. The surface mount technology market is expected to grow at a compound annual growth rate of 5.8% until 2030. Driven by skyrocketing demand for portable electronics and miniaturized electronic components, surface mount technology offers many benefits for custom electronics manufacturing. Here, we will take a closer look at the advantages of this technology and how it impacts product quality.

If you’re ready to elevate your custom electronic assemblies, reach out to the expert team at Siemens Manufacturing today.

Understanding Surface Mount Technology and its Role in Manufacturing

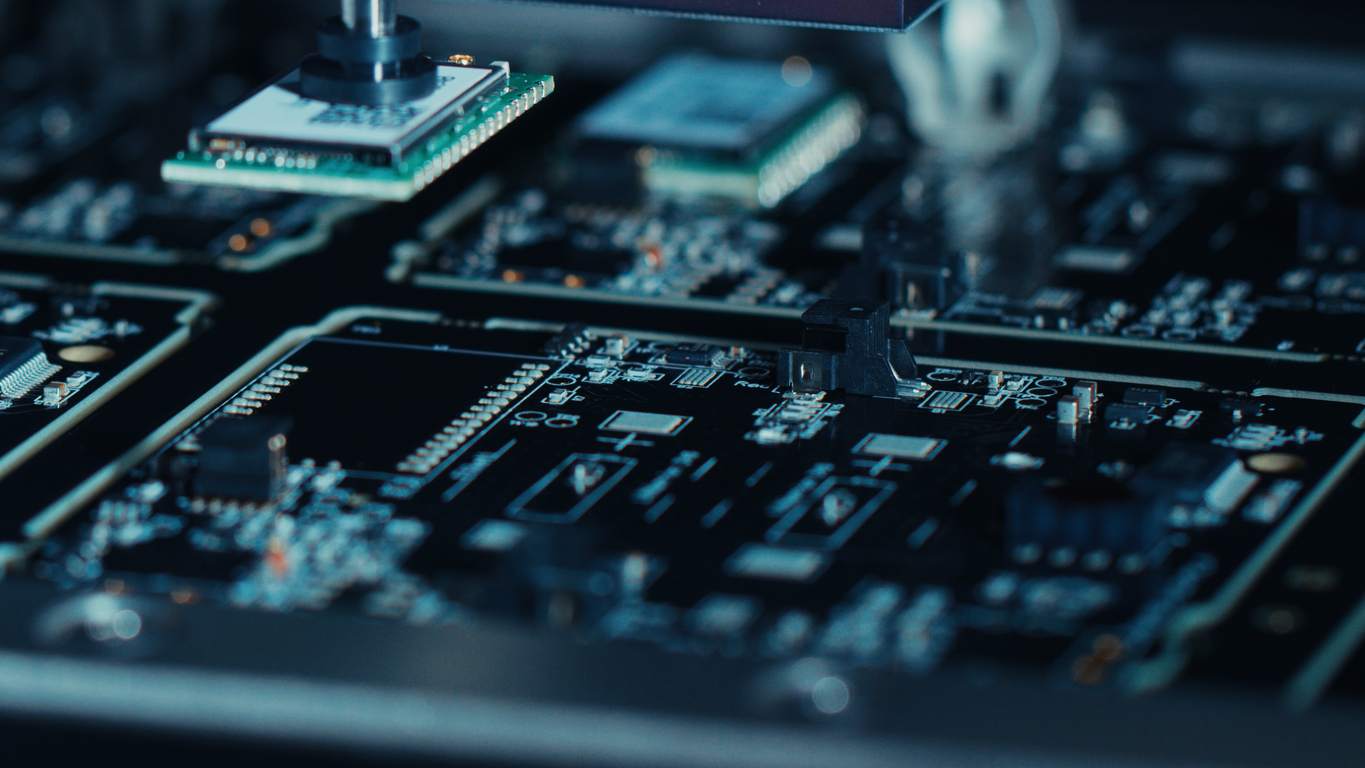

First, it’s important to dive into the process so you can understand how it benefits custom electronics products. Surface mount technology is a manufacturing method in which electronic components are mounted to the surface of a printed circuit board.

There are various processes involved in surface mount technology. Solder paste is a mixture of powdered solder and flux, which is a sticky substance, and this mixture is applied to the printed circuit board by a printer using a pre-made stencil. The solder paste is used to connect the solder pads and surface mount components.

Then components are placed on the printed circuit board using a machine that needs to be incredibly accurate and fast. At Siemens Manufacturing, we have the capacity to place 1 million surface mounts per day. These components are inspected to ensure they have been placed correctly.

The reflow soldering process then begins. Here, the printed circuit board is placed into a reflow soldering oven where, using heat, the solder paste is transformed into a solder. The PCB is then inspected to ensure there are no errors and that the product quality is as expected.

What Are the Benefits of Surface Mount Technology?

Surface mount technology can lead to faster assembly due to the use of automation. Thousands of components can typically be placed per hour, resulting in shorter lead times and reduced labor costs. This manufacturing method is also incredibly affordable due to lower assembly and material expenses.

In addition, this process leads to improved electrical performance and components that function consistently. With this manufacturing method, smaller and more flexible components can be mounted on both sides of the printed circuit board, making for more compact and lightweight PCBs.

Diving into Real-World Applications

This process is used often within various industries. For instance, in the automotive industry, it is used for components within infotainment systems, as well as in electric vehicle manufacturing. The medical industry uses this process in the production of medical instrumentation, x-ray equipment, and important medical devices like blood glucose meters. The communication sector also uses surface mount technology in the manufacturing of smartphones and tablets.

At Siemens Manufacturing, We’ve Perfected Our Surface Mount Technology Services

At Siemens Manufacturing, we are well-equipped to provide you with the high-quality surface mount technology services you require. We have seven surface mount lines, and place 1 million surface mounts per day, allowing us to reduce manufacturing times and save you money.

In addition, we have a vast range of other valuable capabilities, including through hole assembly and BGA assembly. We also offer box build assembly, conformal coating services, and x-ray inspection. Quality is one of our top priorities, and we provide comprehensive automated optical inspection services to ensure our final products meet customer expectations. Our product testing services include in-circuit testing, functional testing, thermal, and much more.

Our market experience is just as vast as our capabilities. We serve the automotive, industrial, medical and instrumentation, construction, food services, military, communication, gaming, and agriculture markets. No matter what your application, we are able to assist you with exceptional custom electronics manufacturing.

As an ISO 9001:2015 registered company, we ensure that all of our processes adhere to the highest industry standards. We are always ready to support our customers with whatever they may need. Contact Siemens Manufacturing today to learn how our surface mount technology services can boost the quality of your next project.