When sourcing contract electronics services, the level of detail in your request for quote (RFQ) can make or break a project. A clear, comprehensive RFQ doesn’t just help you get faster pricing; it ensures you get a quote based on real requirements, not assumptions. Whether you’re ordering PCB assemblies, full box builds, or custom control panels, taking the time to prepare your RFQ correctly helps avoid delays, surprise costs, or mismatched expectations.

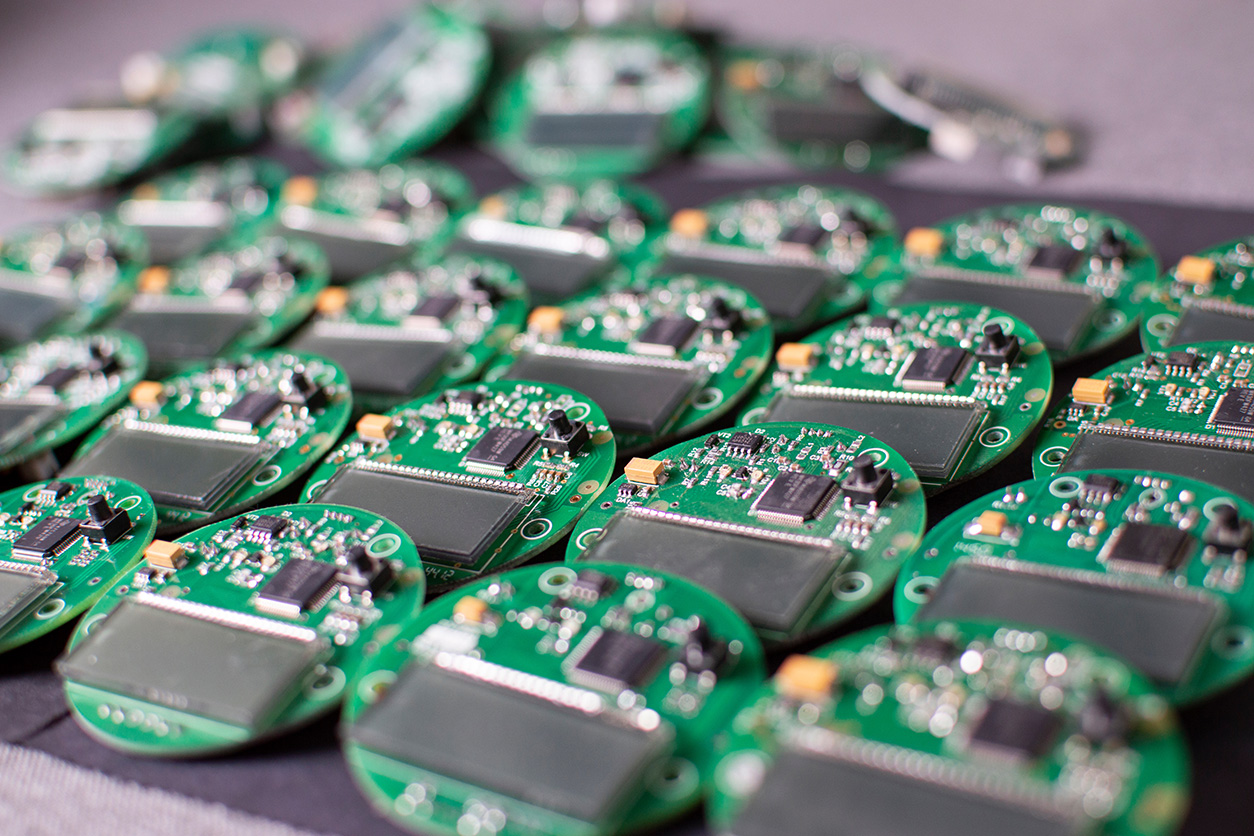

At Siemens Manufacturing, we’ve worked with engineers and buyers since 1963 to build reliable, cost-effective electronic assemblies. Our customers come from medical, industrial, automotive, and defense markets, and each project brings unique needs. But the one thing all successful programs have in common is a clear RFQ.

If you want a fast and accurate quote for your next contract electronics project, we are providing some tips on what to include.

An RFI Before RFQ for Your Contract Electronics

Start by confirming you’re talking to the right companies. Before sending an RFQ, consider issuing a request for information (RFI) to a short list of potential partners. It’s a quick way to evaluate if a potential partner has the technical capabilities, certifications, responsiveness, and capacity your project demands. You’ll want to ask how much of the assembly process is done in-house, whether they build test fixtures, and how they handle component sourcing and shortages.

For example, Siemens operates out of three locations—two in Illinois and one in Hermosillo, Mexico—and all facilities are ISO 9001 certified. We perform surface mount, through-hole, and box build assembly in-house and invest in automation, inspection, and testing systems to maintain high-quality standards. Our ability to shift production between sites also helps mitigate supply chain disruptions, something offshore-only suppliers simply can’t match.

What to Include in Your RFQ Package

Once you’ve narrowed down your vendor list, it’s time to build a complete RFQ package.

Project Scope – Start with a clear project scope. Define whether you need prototypes, production quantities, or both. Specify expected order volumes, release schedules, and any future scaling plans. If you need engineering input, test development, or support sourcing long lead-time parts, include that as well. Also include:

- RoHS Compliance Requirements if applicable

- Listing of any customer-supplied components

- Any Special customer arrangements or price agreements with any component suppliers

- Special First Article Requirements

- Quote Due Date

Product Description – Describe the product. What does it do? What kind of environment will it operate in? Share critical mechanical and electrical specifications, and don’t leave out requirements like conformal coating, ESD handling, or potting. Siemens, for example, operates four conformal coating machines and can run electrodynamic vibration testing and thermal chamber testing in-house—features often required for products in harsh or regulated environments. We will need to know:

- Printed Circuit Board Requirements

- Board Material

- Board Layers and dimensions

- Gerbers

- Fabrication/drill drawing (in PDF format)

- Identify programmed parts and specify who will be programming the component.

- Conformal coating requirements

- Identify/specify keep out areas

- Specify the material/process/Specification

Bill OF Materials (BOM) – Your BOM should be clean and complete, with part numbers, descriptions, and an approved vendor list if applicable. If you allow alternates, state that clearly. Siemens regularly helps customers identify alternate components and sources to avoid long lead times or obsolescence. In some cases, we offer stocking programs that allow flexibility if specifications change midstream.

An accurate and complete Bill of Materials (in Excel format) should include:

- Component Manufacturers

- Manufacturer part number

- Brief description of the part

- Quantity per assembly

- Reference designators

Documentation – Documentation is critical. Include Gerber or ODB++ files, fabrication and assembly drawings, netlists, and any 3D models you have. Be sure to point out any requirements that differ from IPC standards so they don’t get overlooked. Over-specifying can drive up costs; under-specifying leads to gaps that may not be caught until production. Be sure to include:

- Assembly drawing and schematic (both in PDF format)

- Schematic not required to quote but desired at time of PO

- Metal fabrication and cable drawings, if applicable

Testing and Inspection – Testing and inspection requirements should be part of the initial quote request, not added later. Do you need in-circuit testing, AOI, X-ray, or functional testing? Siemens offers all of these, including building custom test fixtures using Agilent systems. We also use X-ray analysis to verify hidden solder joints and detect counterfeit parts. Our internal processes follow counterfeit mitigation standards and full component traceability, which is especially important for medical, defense, or mission-critical assemblies.

Packaging and Delivery – Finally, outline your expectations for packaging and delivery. If your assemblies require special ESD-safe packaging, serialized labeling, or specific pallet configurations, those need to be part of your RFQ. Missed details at this stage often show up as added costs later.

Ready to Quote?

Siemens Manufacturing has supported OEMs across industries with scalable, high-quality contract electronics services. From prototype to production, we deliver fast response times, technical expertise, and the flexibility to meet your schedule and budget.

To start a quote or discuss your project, contact us. Let’s talk about how we can support your next build.